Solid wall insulation – Window Sills

When solid wall insulation is installed on the external walls of a property it is normally 10cm thick or more. What this means is that the sill of previously installed windows will stop well before the edge of the insulation. This doesn’t look great to be honest and could cause issues with water runoff, so the sills need to be extended out beyond the edge of the external solid wall insulation to provide an attractive end finish. Click on the image below to learn more about water ingress and damp.

In an ideal world, we recommend replacing the windows at the same time as getting the insulation works done. The reason for this is twofold; the first is that if you come to replace the windows in the future, the process of removing and refitting them doesn’t compromise the integrity of the solid wall insulation. The second reason is that the sills can been ‘pre-extended’ when the windows are made, so if for example you have wooden sash windows being installed – the sills on the new window already have taken into account the additional 10cm of insulation, so when they are in and the insulation is installed they look great.

For many of us though, the cost involved with replacing windows and doing external solid wall insulation at the same time is just too great. So when it comes to extending window sills what options do you have?

XPS or uPVC sills to match existing window profile

Well the first thing to consider is what the existing sill looks like, the idea is to keep the look of the extended sill as close to the original as possible. If the existing sill is made of concrete, by far the best way of extending it is to use XPS. XPS is a really strong type of polystyrene so can take the additional impacts and loads that you might expect from normal window sills. The XPS is treated in the same way as the insulation, but many of our customers do decide to go with a slightly different colour render to enhance the fact the sill protrudes out of the solid wall insulation!

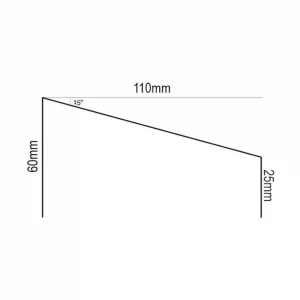

If you have uPVC windows in place, the sills tend to be much thinner compared to concrete ones. In this case we use a uPVC sill extension board, which is attached on top of the existing sill using a combination of sill extension board fixings and adhesive.

The final option and definitely the best in our opinion is to use the powder coated stainless steel sills. The great thing about these is that they can be produced to match the existing look of the sill. Have a wooden window fitted in your property? No Problem! We have powder-coated sills that perfectly mimic the look and feel of real wood.

Another advantage of the stainless steel sill is that they are incredibly strong. The sills will outlast the windows in most cases, and the protective powder coating will ensure that it never weathers over time.

Our partners at EWI Store discuss the function of sills, beads, and verge trims here, so click through and have a read!

At Be Constructive we give our clients the option to install any type of window sill when we insulate the external walls of the property. We obviously will give guidance where we can, but at the end of the process we want the customer to be happy with their new-look home!

1 comment

Hi there,I read your new stuff named “Close window” like every week.Your story-telling style is awesome, keep up the good work! And you can look our website about http://www.ewipro.co.uk