Scratch render

Scratch render is a type of rendering that involves applying a layer of mortar to a wall or other surface and then using a scratching tool to create a textured finish. This finish can be used for both interior and exterior surfaces and is particularly popular for its durability and ability to withstand harsh weather conditions.

The scratch render finish provides a coarse texture that helps to conceal any imperfections in the surface, making it a popular choice for renovation projects. It also offers a great level of water resistance, which makes it ideal for areas with high levels of moisture, such as bathrooms or basements.

The best mix for scratch coat render typically consists of a mixture of cement, sand, and water. The proportions of these materials can vary depending on the desired finish, but a typical mix would be one part cement to four parts sand. The mix should be moistened before application, but not too wet, as this can cause shrinkage and cracking.

The scratch coat is the first layer of the render system and is applied directly to the surface. It provides a base for the subsequent coats of render to adhere to and helps to create a level surface. This layer is typically applied with a trowel and then scratched to provide a key for the subsequent coats of render to bond to.

In summary, scratch render is a popular choice for its durability and ability to withstand harsh weather conditions. The best mix for scratch coat render typically consists of a mixture of cement, sand, and water, and the scratch coat is the first layer of the render system, providing a base for subsequent coats of render.

Scratch render colors

Scratch render is available in a variety of colors, allowing homeowners and builders to choose the best color to match their desired aesthetic. The color options for scratch render may vary depending on the manufacturer and the type of render used. However, most manufacturers offer a wide range of colors to choose from, including natural tones such as white, cream, beige, and gray, as well as more vibrant colors like red, blue, green, and yellow.

Some manufacturers offer custom color options, allowing homeowners and builders to create a unique look that fits their specific needs. This is often achieved by adding pigments to the base mix, which can create a wide range of color options. Some manufacturers also offer a range of finishes, including smooth and textured finishes, to further customize the look of the scratch render.

It is important to note that the color of scratch render can be affected by a variety of factors, including weather conditions, sunlight exposure, and the type of surface it is applied to. Therefore, it is important to choose a high-quality, UV-stable scratch render to ensure that the color remains consistent over time.

Ultimately, the color of scratch render is a personal choice and should be selected based on the desired aesthetic, surrounding environment, and practical considerations. It is recommended to consult with a professional installer or supplier to select the best color option for your specific project.

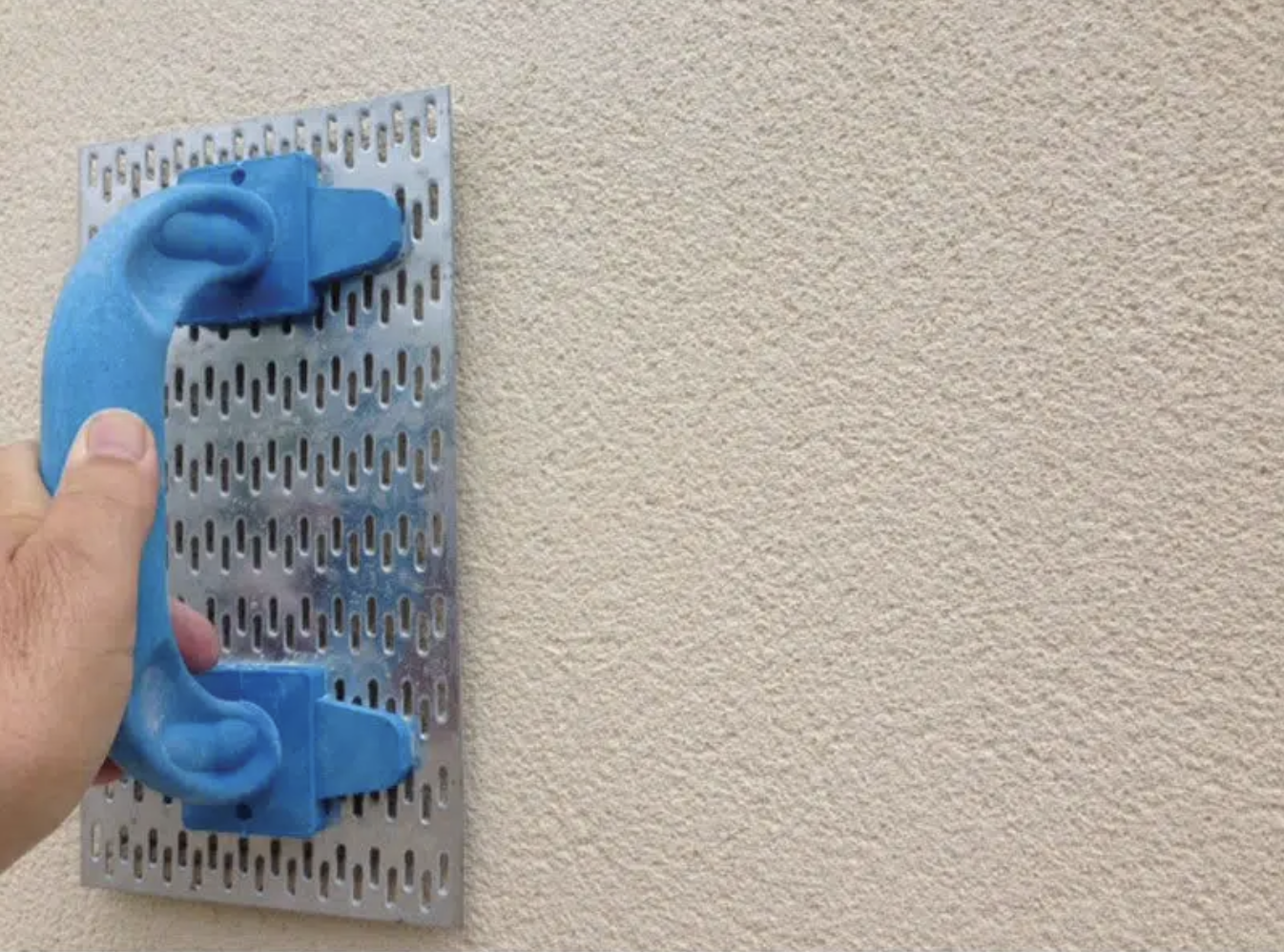

Scratch render tool

The scratch render tool is a specialized tool used to create a textured finish on the surface of the scratch render. The tool is typically made of metal or plastic and has a serrated edge that is used to create a pattern of lines or grooves on the surface of the render.

The most common type of scratch render tool is the scratch comb, which is a metal or plastic comb-shaped tool with serrated edges. The comb is used to create a series of parallel lines or grooves in the surface of the scratch render. These lines or grooves create a key for the subsequent coats of render to bond to, improving the adhesion and overall strength of the render system.

Other types of scratch render tools may include trowels, floats, or other textured tools, which can be used to create a variety of different patterns and textures on the surface of the render. These tools are typically used in conjunction with the scratch comb to create a unique and customized finish.

It is important to use the correct scratch render tool for the specific type of render being used and to follow the manufacturer's recommendations for application and finishing. Improper use of the scratch render tool can result in a weak or unstable finish, which can lead to cracking, peeling, or other damage over time.

Scratch render can be painted

Yes, scratch render can be painted using EWI Pro silicone paint. EWI Pro silicone paint is a high-quality, weather-resistant paint that is specifically designed for use on external insulation and rendering systems. It is an ideal choice for painting scratch render, as it offers excellent adhesion, durability, and water resistance.

Before painting scratch render, it is important to ensure that the surface is clean and free of any dust, debris, or other contaminants that may affect the adhesion of the paint. Any cracks or defects in the surface of the render should be repaired prior to painting, and the surface should be allowed to dry completely before applying the paint.

To paint scratch render using EWI Pro silicone paint, follow these steps:

- Prepare the surface: Clean the surface of the scratch render and repair any cracks or defects in the surface.

- Apply a base coat: Apply a base coat of EWI Pro silicone primer using a roller or brush. This will help to improve the adhesion of the paint and provide a consistent base color.

- Apply the paint: Once the primer has dried, apply the EWI Pro silicone paint using a roller or brush. It is important to follow the manufacturer's instructions for application and drying times.

- Apply a second coat: Depending on the desired finish and the color of the paint, a second coat may be necessary to achieve the desired coverage and color.

- Allow to dry: Allow the paint to dry completely before exposing the surface to weather or other elements.

Overall, EWI Pro silicone paint is an excellent choice for painting scratch render, as it provides a durable, weather-resistant finish that can withstand harsh weather conditions and other environmental factors.

Scratch render and external wall insulation systems.

Scratch render can be used on external wall insulation systems, but it can be prone to cracking over time due to the movement of the insulation and the substrate. This can lead to water penetration and damage to the insulation system, which can compromise its effectiveness.

A better option for external wall insulation systems is to use a silicone render system. Silicone render is a more flexible and elastic material than traditional scratch render, which makes it less prone to cracking and more resistant to water penetration. This can help to improve the durability and longevity of the insulation system, reducing the need for maintenance and repairs over time.

Silicone render systems also offer a wider range of colors and finishes than traditional scratch render, allowing homeowners and builders to create a customized look that fits their specific needs. The finish is highly weather-resistant, meaning it will not fade or discolor over time, and it can be cleaned easily with water.

Overall, while scratch render can be used on external wall insulation systems, a silicone render system is a better option due to its greater flexibility and resistance to cracking and water penetration. It is important to choose a high-quality system from a reputable manufacturer and to follow the manufacturer's instructions for application and maintenance to ensure the best possible results.

Scratch render can be prone to cracking or chipping if it is not applied correctly or if it is exposed to excessive stress or movement. While it is generally a durable and weather-resistant finish, it is important to use a high-quality, flexible render that can accommodate the movement of the building without cracking or flaking.

If scratch render is applied correctly and allowed to dry fully, it should not be easy to scratch. However, if the surface of the render is damaged or compromised in some way, such as by impact or abrasion, it may be more prone to scratching or chipping.

To prevent scratching or chipping, it is important to take steps to protect the surface of the scratch render. This may include avoiding contact with sharp or abrasive objects, using a protective coating or sealant, or applying a second layer of render or finish coat for added durability.

Overall, scratch render can provide a durable and attractive finish for exterior and interior surfaces, but it is important to choose the right type of render for the specific project and to follow proper application techniques to ensure a high-quality, long-lasting finish.

Scratch render is generally considered to be a long-lasting product when applied correctly and maintained properly. One of the key benefits of scratch render is its durability and ability to withstand harsh weather conditions, making it an ideal choice for exterior surfaces.

However, the lifespan of scratch render can vary depending on a number of factors, including the quality of the render used, the conditions in which it is applied, and the level of maintenance it receives. If scratch render is applied correctly and maintained properly, it can last for many years without the need for significant repairs or replacement.

To ensure the longevity of scratch render, it is important to use a high-quality, flexible render that can accommodate the movement of the building without cracking or flaking. It is also important to follow proper application techniques, such as applying the correct thickness of render and allowing sufficient drying time, to ensure a strong and stable finish.

Regular maintenance, such as cleaning and repairing any cracks or defects in the surface, can also help to extend the lifespan of scratch render. Ultimately, the lifespan of scratch render will depend on a variety of factors, but with proper installation and maintenance, it can provide a durable and long-lasting finish for both interior and exterior surfaces.

Scratch render finishes

Scratch render finishes are typically textured and can be applied in a variety of patterns and textures, depending on the desired look and functionality of the surface. The scratch render finish is created by using a scratch comb or other specialized tool to create a pattern of lines or grooves on the surface of the render, which provides a key for subsequent layers of render or coatings to bond to.

Some common types of scratch render finishes include:

- Coarse scratch: A heavily textured finish that is commonly used for exterior surfaces. It provides a rough, durable surface that is resistant to weather and other environmental factors.

- Fine scratch: A smoother, more refined finish that is commonly used for interior surfaces. It provides a more subtle texture that is ideal for painting or other decorative finishes.

- Dragged finish: A finish that is created by dragging a specialized tool over the surface of the render. It creates a unique, irregular pattern that can add visual interest to the surface.

- Tyrolean finish: A finish that is created by using a specialized machine to spray the surface